Timber construction in the urban context

Current developments in the sustainable use of resources and the recyclability of building materials offer the opportunity to build flat components such as floor slabs and walls using wooden building materials, e.g., cross laminated timber, frameworks and composite structures. Where reinforced concrete has stagnated in its original form and way of being processed, flat wooden construction elements offer great advantages and development opportunities, for example, due to their weight and high degree of prefabrication.

Before a house is built, the decision is made in the planning stage about the building materials to be used. This decision also determines the materials that will surround the future residents – making it not only an economic and technical consideration, but also an emotional one. Regardless of whether the aim is to build as cost-effectively as possible, to prioritise health and sustainability, to take advantage of structural benefits or to enhance the sensory experience of a space, one material proves compelling in every respect: wood. Exposed timber ceilings and façades create a pleasant, soft acoustic environment, while the natural scent of wood conveys a sense of fresh, healthy air. From a structural standpoint, this innovative construction method is on par with solid construction; ecologically, timber construction offers numerous advantages.

The advantages of timber as a building material are particularly striking when compared directly to traditional solid construction methods. Locally sourced wood involves short transport routes, has natural insulating properties and, if necessary, can be easily replaced and returned to the material cycle. While materials like metal or cement usually have only one key property, wood combines tensile and compressive strength – an unbeatable advantage.

Timber elements are pre-assembled by experienced carpenters in factory halls, doors and windows are fitted precisely and technical components are installed. These prefabricated parts are then delivered to the construction site and assembled; no painting is required. There’s also no need for masonry work, mixing cement or building materials that only fulfil their purpose as complex material systems that later need to be laboriously separated for recycling. Another major saving lies in the thermal energy consumption. Conventional building materials require high levels of heat during their production – steel has to be melted and bricks fired. Wood, by contrast, does not require this energy input, and construction time is significantly reduced. The impact on local residents is greatly minimised, and the high accuracy of fit guarantees a smooth and efficient assembly.

Photo Benjamin Antony Monn

The approach to life cycle assessment (LCA) – which considers both the extraction of resources from the environment and their environmental impact – clearly highlights the ecological benefits of timber construction. Renewable raw materials such as wood, which require very little processing energy, perform significantly better in this regard than building materials made from fossil resources. Timber buildings have traditionally offered superior thermal insulation. Due to the lower thermal conductivity of wood, wall constructions in timber buildings can be more space-efficient than in solid construction while achieving the same U-values – resulting in increased usable living space. In terms of insulation performance, timber construction outperforms solid construction. When it comes to sound and fire protection, timber construction demands greater precision in planning and execution than solid construction, but this can easily be compensated for by industrial prefabrication in workshops and the higher use of computer-controlled machinery.

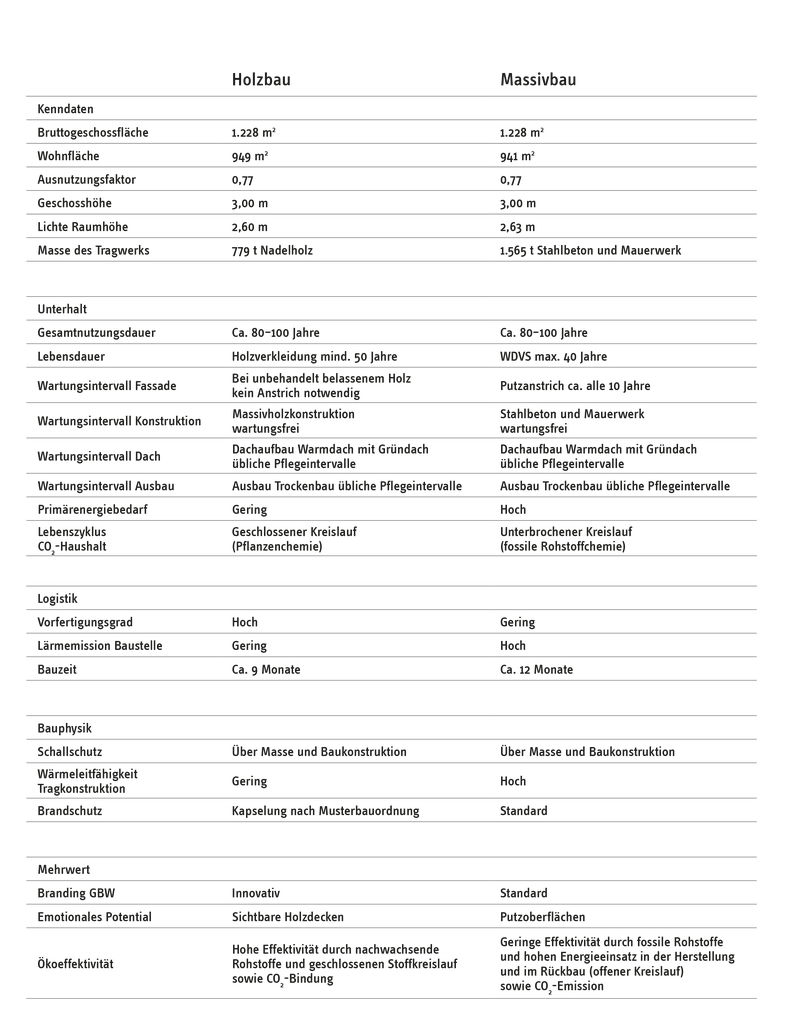

Vergleich der Bauweisen

Photo zillerplus

The timber construction on Mainzer Straße uses approximately 360 cubic metres of softwood. This corresponds to a dry weight of around 144 tonnes – whereas the same building in solid construction would contain about 1,565 tonnes of reinforced concrete and masonry. To produce this amount of wood, trees absorbed around 264 tonnes of CO₂ from the atmosphere through photosynthesis (equivalent to roughly 105,000 litres of crude oil) by the time they were harvested. This CO₂ is now stored – captured – in the timber structure, at least for the lifespan of the building. Long after the average lifespan of a building, the wood used in the construction will rot and release the stored CO₂ back into the atmosphere or can be used for energy generation.